- English

- Sales & Support:0086 755 89315501 / 18688718622

| Place of Origin: | China |

| Brand Name: | Die Cut Mylar Bags |

| Certification: | ISO、SGS |

| Model Number: | Special Shape Bags-CH021 |

| Minimum Order Quantity: | 200pieces |

|---|---|

| Price: | Price Based On Product Design |

| Packaging Details: | Carton Box |

| Delivery Time: | 7 to 12 days |

| Payment Terms: | Paypal、T/T、MoneyGram、D/P、D/A、W |

| Supply Ability: | 1200000pcs/Months |

| CUSTOM ORDER: | Accept | COLOR: | Colorful |

| SAMPLE: | Avaialble | THICKNESS: | 50-200microns |

| MATERIAL: | Food Grade Material | SIZE: | Customized Size |

| FEATURE: | Moisture Proof,Recyclable,Security | INDUSTRIAL USE: | Candy,Cookie,Gummy Food Packaging |

About us:

ShenZhen Rainbow Packaging Company is specialized in making 3.5g custom shaped plastic mylar bags for more than 10 years. We make plastic mylar bags are for CBD weed, cookies, gummy product packaging. We support custom shaped bags with rich experience, high quality products, competitive prices and excellent services. We continue to be a leading developer and supplier of flexible packaging solutions. Driven by technology and innovation, Rainbow is at the forefront of bringing new development to customers and general marketplaces. Rainbow Packing commits ourselves to the pursuit of excellence in customer service and quality assurance. We hope to build long-term relationships with our clients.

What is Shape CBD Die Cut Bag?

Shaped bag is a kind of irregular bag, it breaks the impression that people feel the bag is square, novel, good identification, and more intuitively highlight the product characteristics, for example, designed into the corresponding shape of the fruit slices, so that people can understand the product information at a glance. Compared with traditional bottle packaging, it is more energy efficient and environmentally friendly, and can save storage costs and transportation costs. These advantages of the shaped bag make it widely used in food, daily chemicals, toys, medicine, electronics and other fields.

Die-cut gift bags are unique and visually appealing packaging solutions commonly used for special occasions and gifting purposes. The process of creating these bags involves precise cutting and assembly to achieve the desired shape and design. Below is a detailed introduction to the process of making die-cut gift bags, along with a comparison table:

The production process of die-cut gift bags involves several steps, starting from design and material selection to the final bag assembly. Each stage is crucial in ensuring the bags meet the desired aesthetics and functionality for gift packaging.

1.Design and Artwork: The process begins with designing the artwork for the die-cut gift bags, incorporating customized elements like logos, graphics, and unique designs.

2.Material Selection: After finalizing the design, appropriate materials are chosen based on the bag's intended use and appearance, such as high-quality art paper or specialty paper with specific textures.

3.Die Creation: A die is custom-made based on the bag's design, which will be used for precise cutting during the production process.

4.Printing (Optional): If required, the selected materials are printed with the custom-designed artwork using advanced printing techniques.

5.Die Cutting: The die-cutting process involves using the custom-made die to cut the bags into the desired shape, creating intricate patterns and handles as specified.

6.Embellishments (Optional): Additional embellishments like ribbons, bows, or foiling can be added to enhance the bag's visual appeal.

7.Handle Attachment (Optional): For bags with integrated handles, the handles are securely attached during this stage.

8.Lamination (Optional): Lamination can be added to provide a glossy or matte finish, further enhancing the bag's appearance and durability.

9.Bag Assembly: The die-cut pieces are then carefully assembled, folded, and glued together to create the final gift bag structure.

10.Quality Control: Each bag undergoes strict quality checks to ensure it meets the desired specifications, including size, shape, printing quality, and overall appearance.

11.Packaging and Distribution: After passing quality control, the finished die-cut gift bags are carefully packaged and distributed to clients or retailers.

| Production Step | Description |

|---|---|

| Design and Artwork | Creating customized artwork and designs for the gift bags. |

| Material Selection | Choosing appropriate materials based on appearance and usage. |

| Die Creation | Custom-making the die based on the bag's design for precise cutting. |

| Printing (Optional) | Adding custom-designed artwork using advanced printing techniques. |

| Die Cutting | Cutting the bags into the desired shape using the custom-made die. |

| Embellishments (Optional) | Adding decorative elements like ribbons, bows, or foiling. |

| Handle Attachment (Optional) | Attaching handles for bags with integrated handles. |

| Lamination (Optional) | Adding lamination for enhanced durability and appearance. |

| Bag Assembly | Assembling, folding, and gluing the die-cut pieces into final bags. |

| Quality Control | Conducting strict checks to ensure the bags meet desired standards. |

| Packaging and Distribution | Packaging and distributing finished gift bags to clients or retailers. |

Q: Can I create custom die-cut gift bags for a specific event or theme?

A: Yes, die-cut gift bags can be designed and customized to match specific events or themes, adding a personal touch to the gift-giving experience.

Q: What types of materials are suitable for adding a luxurious appearance to gift bags?

A: High-quality art paper with specialty finishes like metallic or embossed textures can enhance the bag's luxurious appearance.

Q: Are die-cut gift bags suitable for bulky or heavy items?

A: Die-cut gift bags can be designed to handle a range of items, but it's important to choose appropriate materials and handle reinforcements for heavier gifts.

Q: Can I get a sample of the die-cut gift bag before placing a bulk order?

A: Many manufacturers offer sample orders to ensure the bag's design and appearance meet customer expectations.

Q: Are the bag handles securely attached to prevent tearing?

A: Yes, handles are securely attached during the production process to ensure the bag's durability.

Q: Can I add a company logo or branding on the gift bag?

A: Yes, die-cut gift bags can be customized with company logos, brand colors, and designs, promoting brand identity during gift-giving.

Q: Are there any limitations on the bag's shape for die-cut gift bags?

A: While die-cutting allows for various shapes, certain intricate designs may have practical limitations.

Q: Can I choose a specific finish for the laminated gift bags?

A: Yes, laminated gift bags can have a glossy or matte finish based on the desired appearance and tactile feel.

The process of creating die-cut gift bags involves a combination of design, precise cutting, and assembly to produce visually appealing and functional packaging solutions for gift-giving occasions. The customization options allow businesses and individuals to create unique and memorable gift bags that leave a lasting impression on recipients.

Question 1: Are you a manufacturer?

A:Yes. The address is in Shenzhen, Guangdong. We have been committed to providing professional solutions for the printing and packaging

industry for 16 years. The 5000 square meter factory has 3 floors of production department (including printing, lamination, edge cutting,

material folding, sealing, quality control, packaging, etc.), we have more than 50 production machines and more than 150 workers.

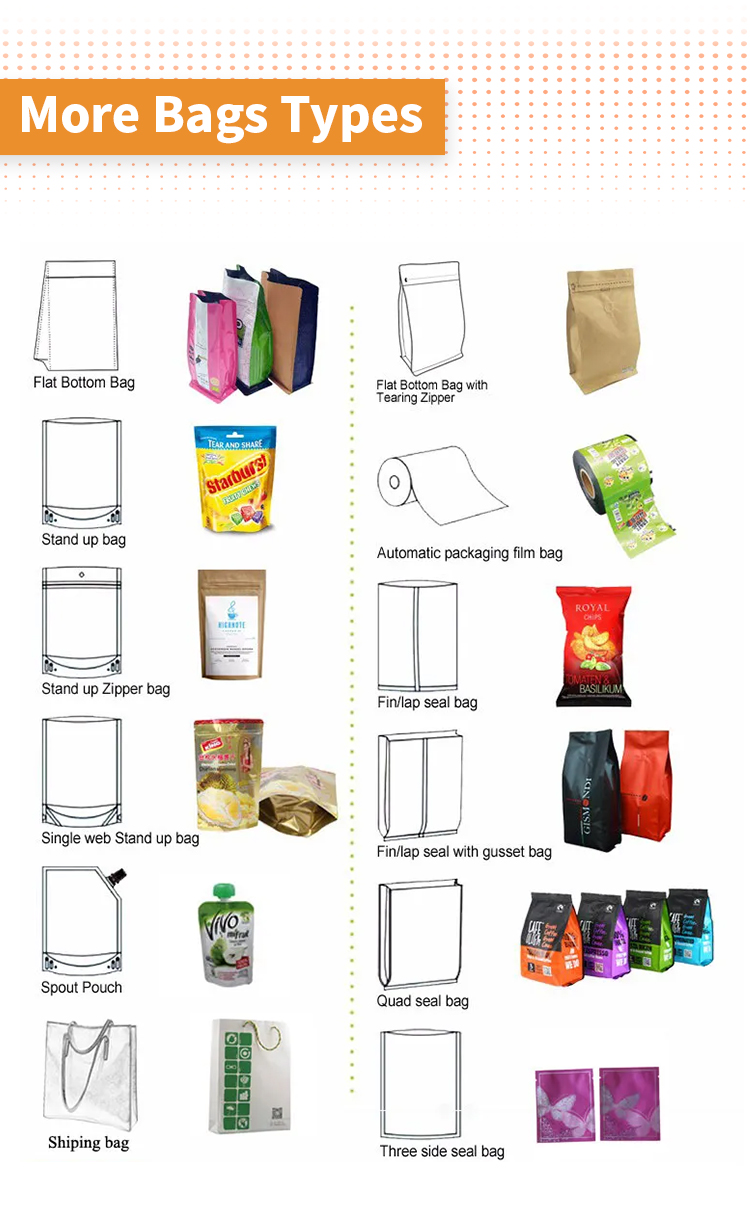

Question 2: What is your production range?

A:We mainly produce bags like stand up pouch, flat bottom bags, kraft paper bags, spout bags, aluminum foil bags, ziplock bags,

middle sealing bags, three-side sealing bags, coffee & tea bags, commodity packaging bags etc..

Question 3: Do you have certification?

A:Yes, we have certification like SGS, (94/62/EC) etc. Files can be shared if needed.

Question 4: What’s your MOQ?

A:MOQ based on your bag details, usually is 10,000pc, it can be negociated. More quantity, more favorable prices.

Question 5: Can I get sample bags?

A: Yes. We can provide you free sample bags with different materials and sizes for your choice and quality checking.

It needs buyer cover the shipping fee.

Question 6: I have a new product and I am looking for the perfect packaging solution. What should I do now?

A:Please contact us through our online service. Experienced service team members will contact you to fully understand your needs and

preferences. Based on this, our team will provide you with a set of packaging solutions, including the best design, materials, dimensions,

etc. to meet your needs.

Question 7: What is your price and how do I get a quote?

A:We are the manufacturer and only the first hand price is here.

Please provide us the following specifications to get a quote:

(1) Bag type (2) size, material (3) thickness (4) printing color (5) quantity (6) artwork design in AI / PDF / CDR

Question 8: What should I do if I find a quality problem when receiving the goods?

A:You can send us feedback, we will check and reply in time.

Address: 5th Floor, Building 6, No.23, Xinbao Second Street, Dalang Town, Dongguan,523786,Guangdong,China. Die cut pouch, die cut bag on sales from our die cut pouch factory, professional die cut bag manufacturer provide die cut pouch, die cut bag, custom die cut bags wholesale and designs